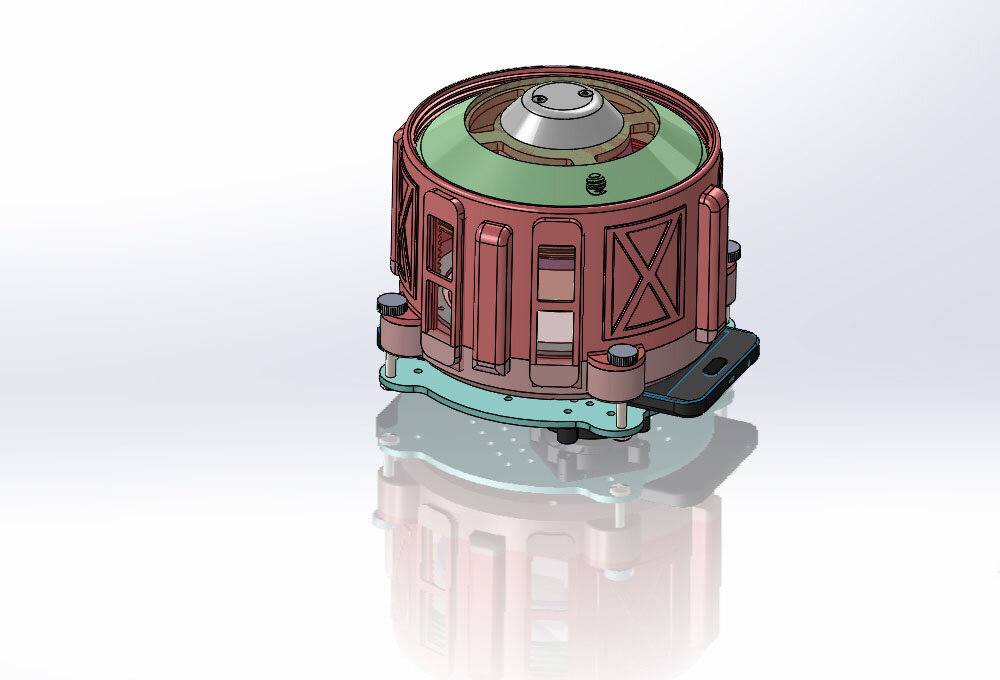

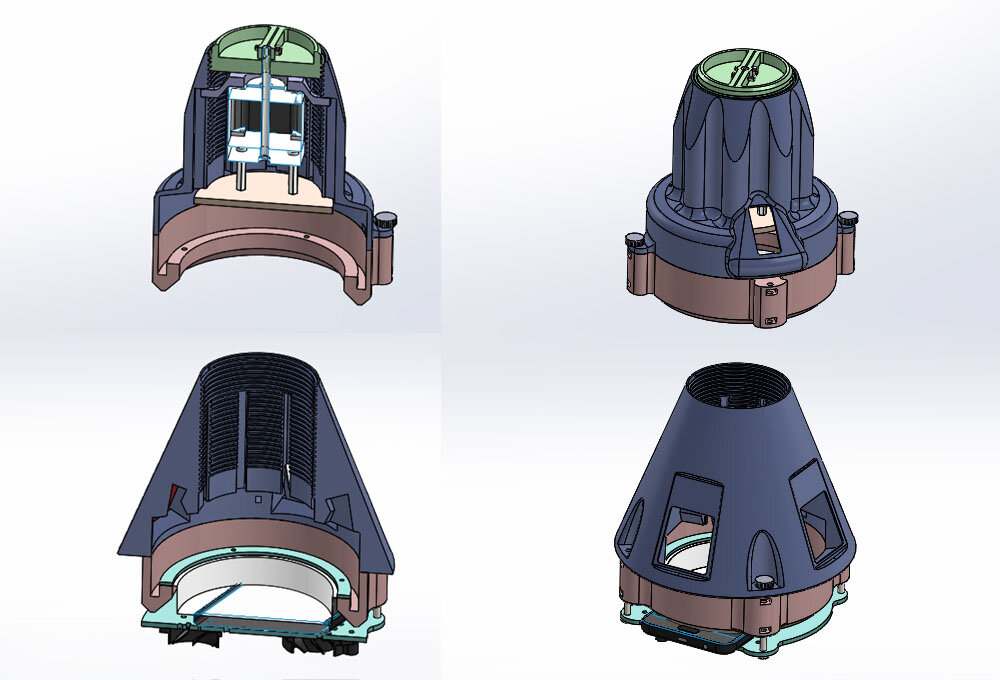

previous design iterations: LumiPot and lumicell

The initial design was a quite strange one and was called ironically “LumiPot”: the body of the 3d printer was a single FFF part, with a large female thread running inside; the tray was attached to the Z stepper motor and to a male threaded part. The movement was vertical only, as some slits into the body prevented unwanted rotation of the tray.

This designed worked quite well, but not all domestic FFF machines were able to 3d print the threaded parts with the correct tolerances; so some hand polishing of the treads was needed and it took quite a lot of time. Another problem was the long printing time of the body part.

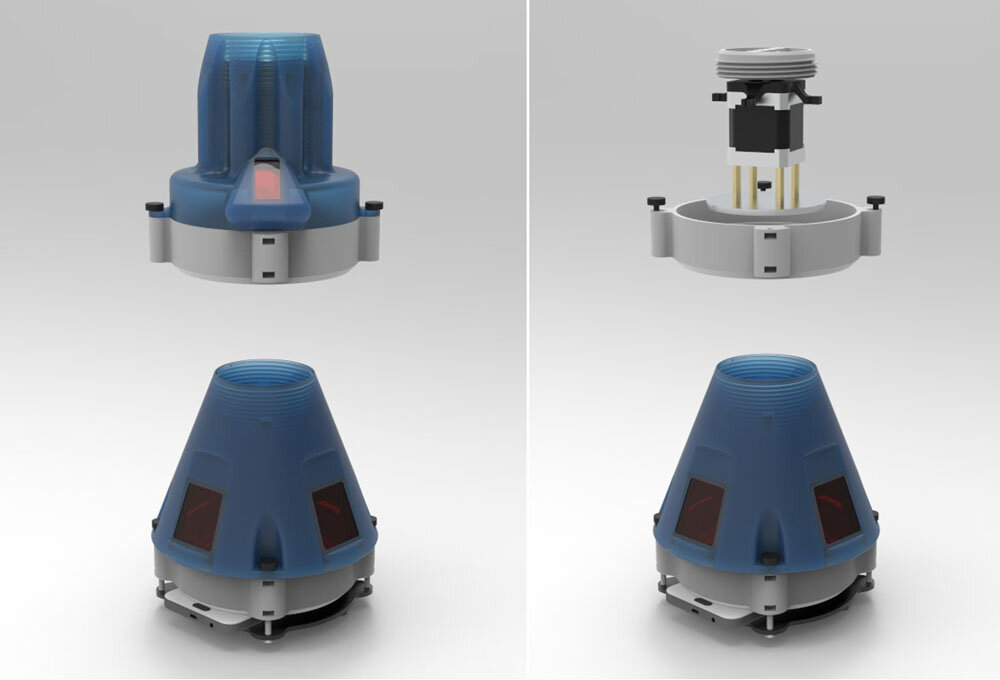

A second iteration, called “LumiCell” was more conical shaped, to reduce the FFF printing time, and to make the thread smaller; some windows were added too, to be filled with Cnc or laser cut orange acylic, in order to see what was happening inside.

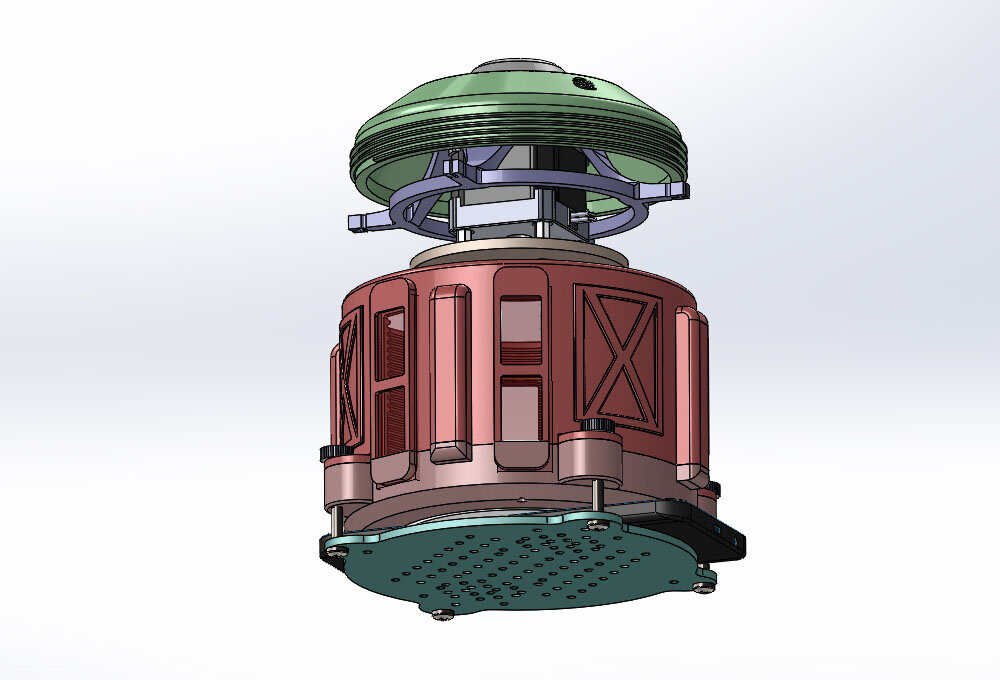

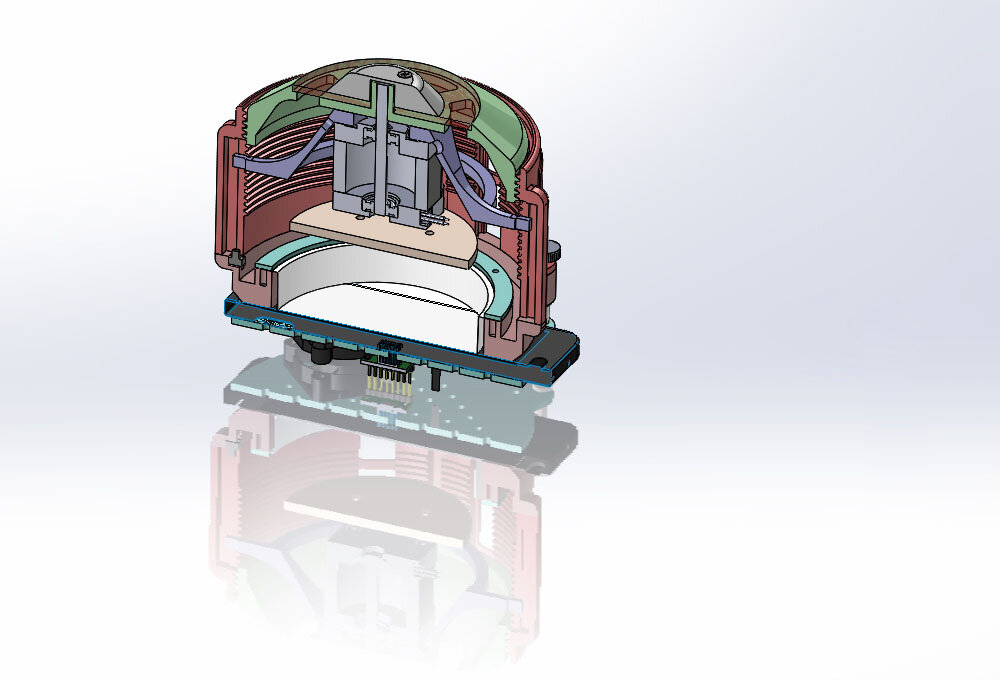

The final LumiBee design uses a more modular approach, so we have two stepper motors, and FFF printed lead screws and nut, and the body is made by 3d printed columns, and laser cut acrylic windows, so the overall printing time of the LumiBee is greatly reduced!