MAKARS SUMMER SCHOOL VOL.IV

THE FIRST TRAINING COURSE FOR DIGITAL FABRICATION AND CULTURAL HERITAGE IN VENETO REGION.

After exploring 3D relief, during the last two days, Makars Summer School course focused on 3D printing.

First of all with Manuela Pipino from Lumi Industries, we tried to understand what 3D printing is.

3D printing is also called additive manufacturing because we need to add material to build an object. While traditional production tools, such as a cutter, subtract material, and are therefore considered subtractive.

We have discovered what its main uses are in general and how 3D printing can be used effectively in preserving and enhancing cultural heritage for:

restoring artifacts missing parts by rebuilding them through 3D printing,

make visible archeological finds that, for their delicacy, cannot not be exhibited,

educate through faithful reproductions of otherwise inaccessible works,

make museums accessible to blind and visually impaired people with tactile paths.

There are several 3D printing technologies, and it is important to learn how their features and peculiarities to know how to use them at the best.

Giulio Bigliardi from 3D Archeolab, introduced the most popular 3D filament printing, showing the different typologies, the materials that can be used on this kind of machines, and consequently what can be achieved.

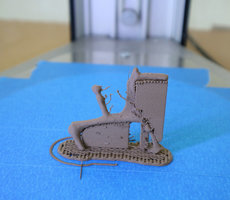

Usually it is used to create medium-sized objects that do not require extreme detail. For printing on the two available filament machines we then selected the largest finds.

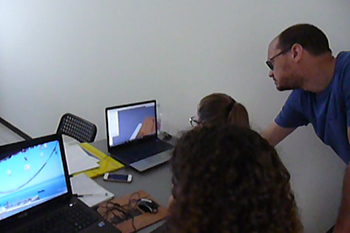

Students have learned that before proceeding to printing it is necessary to prepare 3D models depending on the 3D printing technology.

In the case of filament 3D printing, it is important to choose the best position to print the object, the thickness of the object walls, the fill type and, of course, the thickness of the layers that will be overlapped: the less thick they are, the higher resolution we get.

They have revised and got models ready to be sent to 3D printing

With Manuela, we have instead explored resin 3D printing technology, which is the working field of Lumi Industries.

This technology uses liquid resins that solidify with the light emitted either by a DLP projector either by a UV light laser. Lumi Industries has offered to the students the possibility to explore both types using: LumiForge (DLP 3D printer) and the new Lumipocket LT (laser SLA printer).

Before moving to printing in this case too, the students had to prepare the files with different rules from the one of filament 3D printing.

In resin printing, it is always important to empty objects, but no filling is required. It is essential to create supports and therefore it is important to study the best position to place the object so that the least possible number of supports is built.

For all these operations we learned to work with Meshmixer software, while with NetFab, as free software, we learn how to correct 3D models imperfections which may lead to inaccuracies during printing.

And finally we have 3D printed!

Students have also learned that post-processing work is required after printing, including cleaning of printed models, removing supports which were used for their construction, and finally a exposure under UV light to completely dry models.

And here are our reproductions that have been donated to Museo di Storia Naturale e Archeologia di Montebelluna (TV).

We will be waiting for your at Makars Summer School 2018 edition!