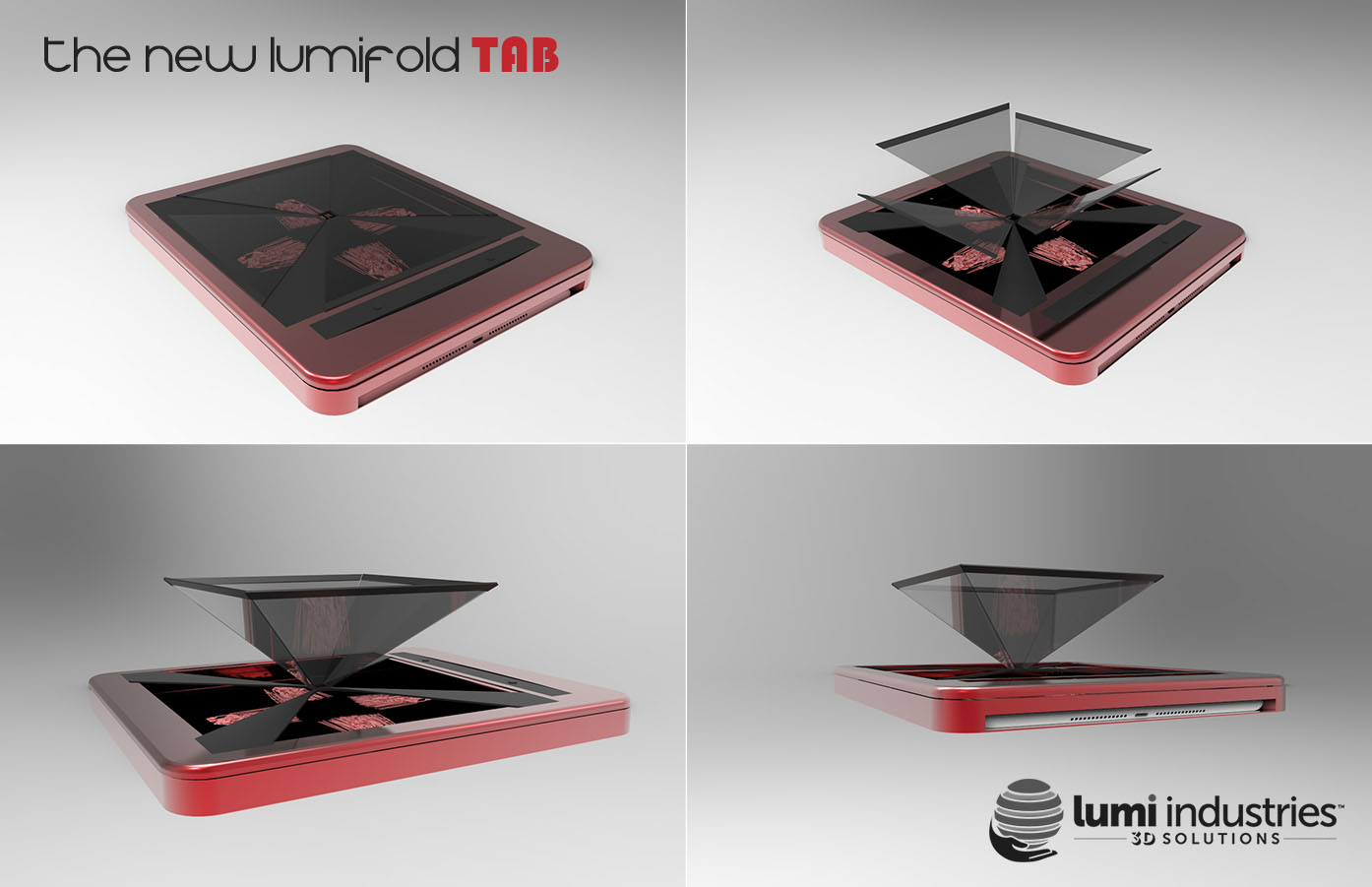

The New Lumifold TB

An innovative resin-based 3D Printer designed to be portable!

The New LumiFold is a revolutionary portable, resin-based 3D printer. It can fit into a suitcase and create detailed 3D parts in a wide range of materials.

There are several scenarios for a portable 3D printer, such as: a teacher can bring a 3D printer in his suitcase and print 3D models during his lessons; doctors can make 3D printed replicas of anatomical parts, for colleagues, to prepare for a complex surgery; live presentations for jewelry/fashion companies, in which it becomes possible to go to the presentation with your 3D Printer and create prototypes together with the customer.

In developing countries and emergency areas, a portable machine capable of 3D printing with great precision can be not only helpful, but a radical step forward for dental and medical care.

How does the New LumiFold work?

A Tablet (iPad Mini) is inserted under the resin Vat, covered with a thin transparent non-stick film. A proprietary App slices and processes the 3D file that the user wants. Once the file is ready, you just click start": the New LumiFold, connected via Bluetooth to the iPad, will move up each time that a layer has been cured thanks to the light emitted by the screen itself.

Tech Specs

3D Printer size: 28 cm *18 cm * 8 cm (turned off and closed)

3D Printer size when fully open: 28 cm * 18 cm * 18 cm MAX

Building area: 10 cm * 10 cm * 10 cm

Resolution: X/Y 78 micron

Resolution Z: up to 25 micron

Resins: Daylight resins

Light source: iPad mini 3/4 (other tablets and even phones can be also used, however the current device was specifically designed for the iPad mini 3/4), and an App has also been designed to work on IOS.

Bluetooth connection between Tablet and 3D Printer

Patented design

New LumiFold TB Awards

The design "New LumiFold: portable 3D Printer" won a Red Dot in the Industry and Tools category at the Red Dot Award: Design Concept 2021

New LumiFoldTB Portable Resin 3d Printer has been granted the Bronze A' Design Award in Manufacturing and Processing Machinery Design Category by the International Design Academy, the grand jury panel of the A' Design Award & Competition which consists of influential press members, established designers, leading academics and prominent entrepreneurs worldwide.

Since 2015, Lumi Industries participates with its futuristic design devices to Manus Awards which rewards the most exciting plastic plain bearing applications produced by Igus, leading manufacturing company of technical components. In the 2019 edition, out of 445 participants from 32 different nations, the New LumiFold TB project is awarded the “ Jury Special Mention”

How it all started

Lumifold first design and prototype, 2013

LumiFold has been our first revolutionary 3D Printer. Launched in 2013, Lumifold, was compact, portable and even foldable!

It was officially presented at the first European Maker Faire in Rome, it was t he protagonist of our first crowdfunding campaign on Indiegogo and it attracted the interest of the international press like The Guardian, since it was the first time that the idea of portability and compactness was introduced into the 3D printing world. This was the starting point of our quest for it.

In fact, we believe that, in a way similar to the evolution of computers from big mainframes to compact personal computers, compactness will help 3D printers to become more and more adopted.

Why compactness and portability

Village Doctor by photographer Shaikh Mohir Uddin

Since the New LumiFold is a portable 3D Printer that can create detailed parts using even certified dental or medical resins for 3D Printing, it can be used to set up a mobile laboratory or dental clinic, that is able to move and provide dental and medical care in emergency areas, and even developing countries.

The evolution of an idea

In 2015 we developed a unique mechanism for the Z-axis of a 3D printer that allows to design extremely compact machines for fast prototyping.

Its most interesting feature is that the total height of the 3D printer, when closed, is smaller than the maximum height of the 3D printed part, as it expands while printing. This system can be integrated in different types of 3D printers and is now patented.

This system can be applied to different 3D printing technologies being them filaments or different type of resin techniques (SLA, DLP, LCD). Our first version is New LumiFold TB, the first compact resin based 3D printer using a normal tablet as light source.

The New Lumifold on Major International publications

Press release images