Only Sunlight and sand to 3D build with Soll-E

Soll-E is an autonomous robotic device, meant to use concentrated sunlight for 3D sintering sand material for the creation of construction parts like bricks, pipe components or other, for structures building in emergency areas, developing countries or new frontiers like the Moon or Mars.

The inspiration

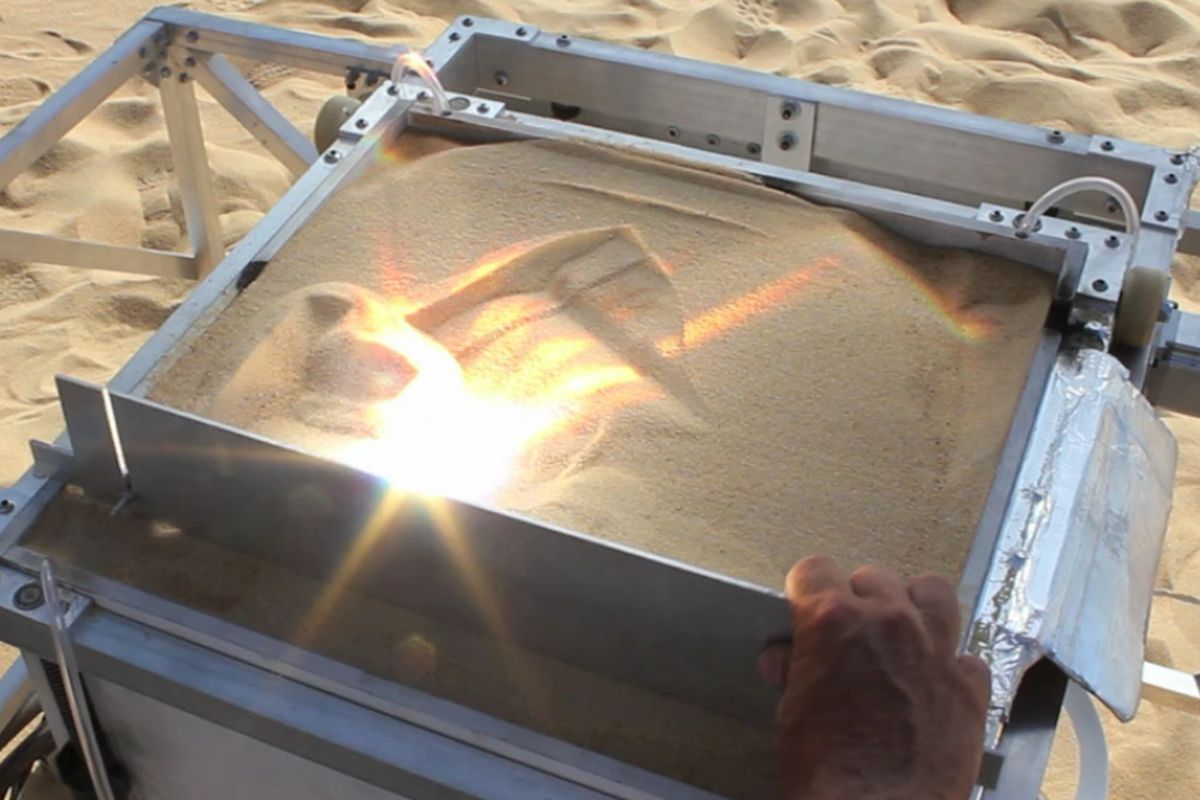

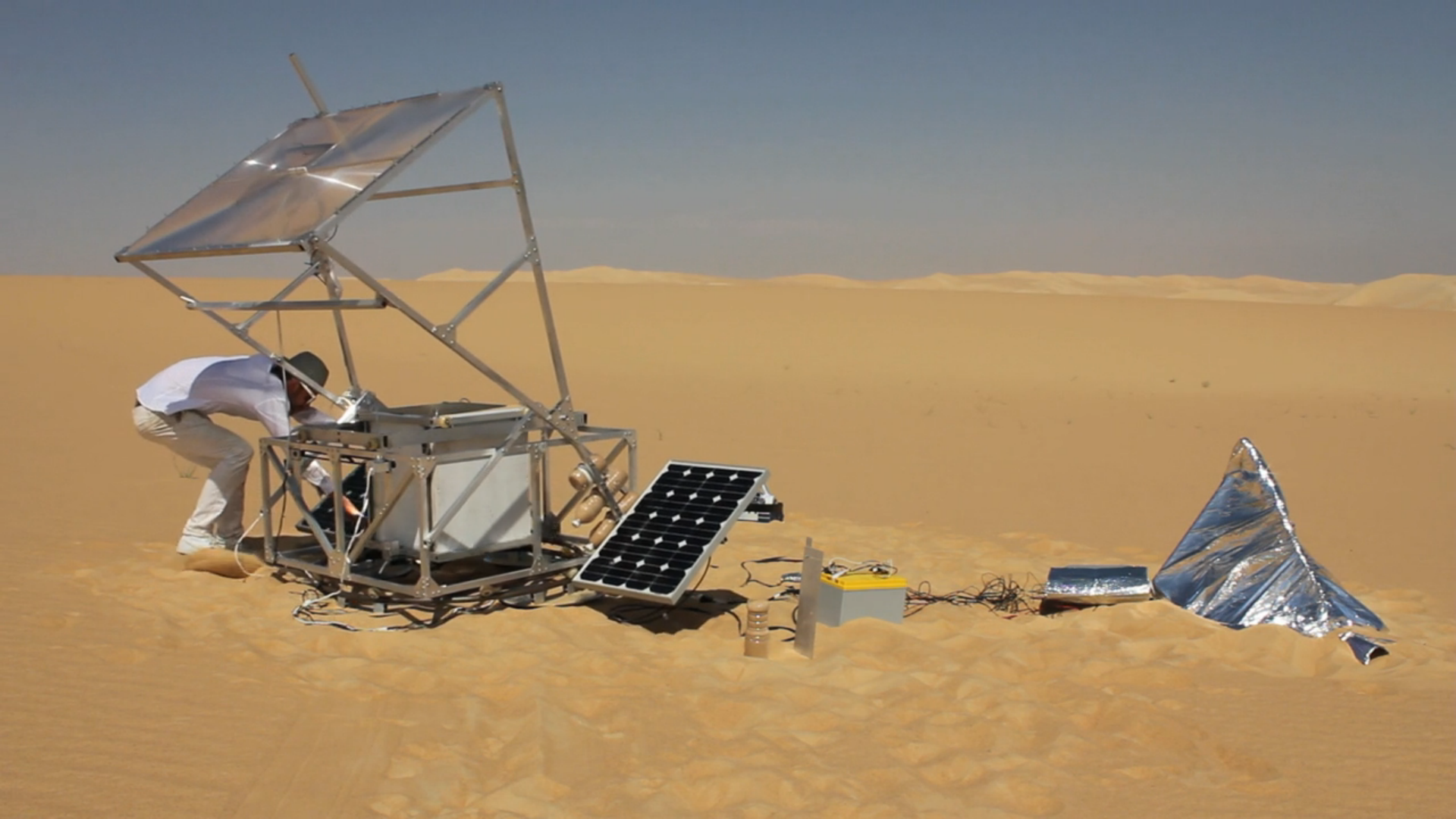

We watched the video by Markus Kayser, who went to the Sahara Desert to successfully test a device “turning sand into glass” through sunlight sintering, and read about the RegoLight project by the ESA aiming to build bricks from moondust.

These projects were a source of inspiration, for our ingenious Founder and CEO, Davide Marin, who, as spare time activity, started thinking about designing a complete autonomous robotic fabricating unit, we call Soll-E. Of course, a dedication to Wall-E, the trash compactor protagonist of a famous animated science movie, which inspired the machine external outlook.

The Philosophy behind Soll-E

Soll-E project is driven by the same philosophy of “Lumi Industries cares Projects”: to do our part to make a better world.

It is still in a very early stage project, however, we want to share it. On one side for the sake of simply sharing our ideas hoping this might contribute to fight a global problem like building in emergency areas, developing countries on in the space, which is at the base of our Maker philosophy, and on the other side in the hope to find companies, associations or institutions willing to collaborate in the development of such an ambitious project.

Images from Markus Kayser tests in the Sahara desert

MIT develop rolling robot that can 3D print buildings

Limitations of current 3D Printing solutions for Developing Countries

Quite big and expensive machines requiring many different peoples during the assembly process and the working process itself,

Extruding a clay wall less than 3m tall requires about 200KW and several cubic meters of water that usually is a very precious resource.

Is it possible to reduce the size of the 3d printing machine and use only resources that do cost nothing and are not at risk of depletion?

Our Idea

Soll-E is a:

totally low-cost autonomous robotic module,

powered with sunlight and use sand as consumable material, and it is not using even a drop of water!

can be left alone in a desert area. It is totally independent during the day while it will close and remain in stand-by mode during the night when sun light is not there.

An integrated GPS system will always show its location and there will be the possibility to operate it remotely.

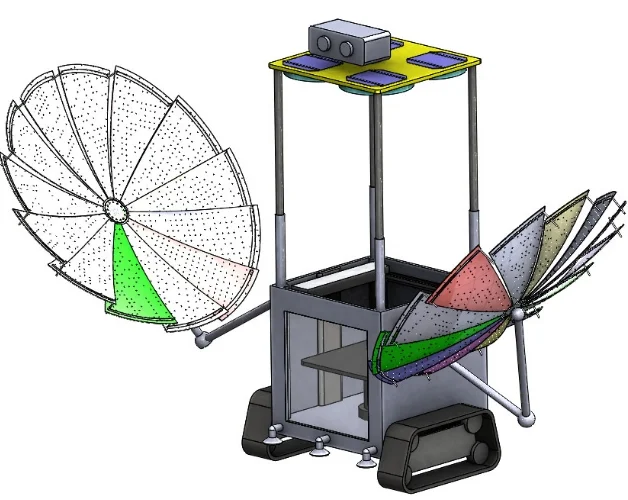

Soll-E Open during light hours

Soll-E closed during dark hours

We believe this system can be used for extreme low-cost building in emergency areas, developing countries or may be new frontiers like the Moon or Mars.

How does it work

Soll-E robotic unit has two folding solar parabolic mirrors, which are going to collect solar sun and transform part of it into power energy for functioning of the unit itself. The remaining part of this solar light will be directed toward a system of mouvable mirrors, which, like what happens in UV laser SLA 3D printing systems, will modulate, focus and direct the light toward the printing bed, inside the robot structure, were the sand from the earth surface has been collected and spread in a thin layer.

The mirror movement will focus the light in a thin but extremely hot and powerful ray, which will follow the precise design we have uploaded and sinter the sand into solid material through a vitrification process.

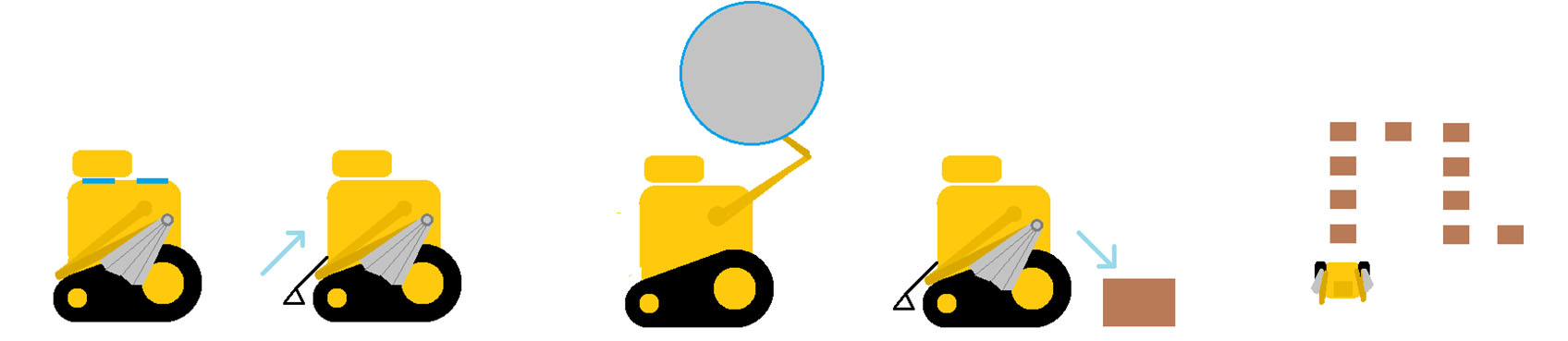

Once one layer is done the robot will collect new material from the ground and spread a new layer ready to be sintered.

The idea is to build simple bricks, and when one brick is done the machine will deposit it on the ground and move forward to build a new brick. The user can then pick up them and assemble them like a Lego puzzle. Bricks, but also pipeline sections, architectural or other 3D parts can be sintered and afterwards used to fabricate buildings or other structures in desert areas at zero cost.

Development stage

The project is still in early stage development. We were able to make some successful tests using focal lenses, to ensure that our assumption was correct: sand can be melted through focused sun light.

A first design of the device in its full parts is ready, next step will be the creation of a working prototype. By next year 2019, we would like to proceed to a first proof of concept which will help us understand what must be adjusted.

We are now looking for Institutions, Universities or private companies interested in this kind of technologies and willing to support our idea and work.

We feel this project can have great resonance and excellent implementations in areas like the Arabic Peninsula, where there is always interest for new technologies in the field of construction and abundance of raw material.

Successful test on beach sand laser sintering

For example, Sheikh Mohammed bin Rashid Al Maktoum, Ruler of Dubai, has announced the ambitious plan for the emirate’s 3D printing strategy, which includes a mandate for 25% of all of Dubai’s buildings to be 3D printed as part of their construction by 2030. Soll-E can be an interesting technology to fulfil their target in a total green and low-cost way.